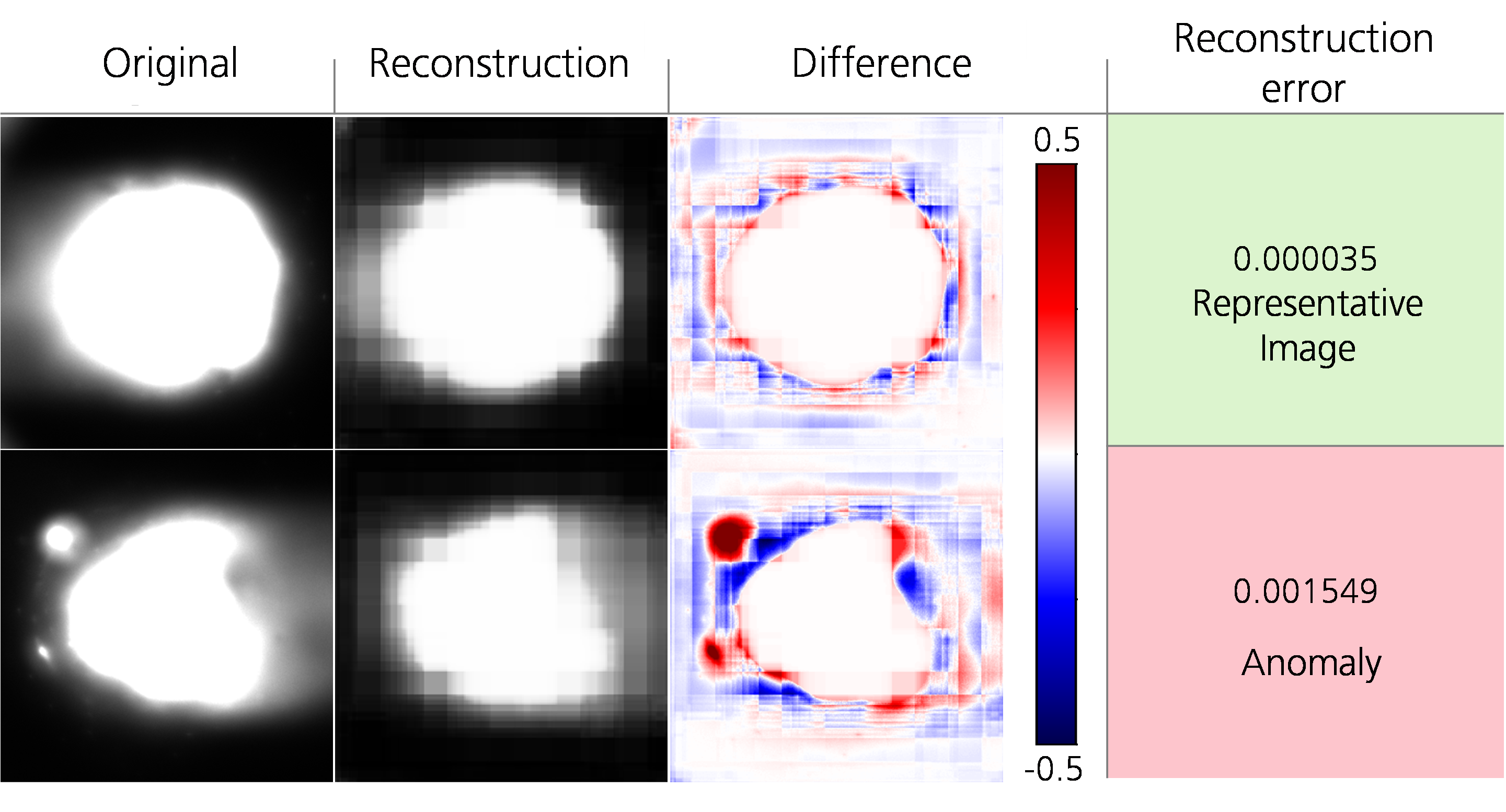

The current sprint is exploring how autoencoder models in unsupervised learning can analyze camera data from Laser Material Deposition (LMD) processes. By linking the model's reconstruction errors with the LMD's toolpath coordinates, the team aims to identify any image anomalies and how they relate to the quality of the manufactured parts, such as detecting surface adhesions more effectively.

| Topic Fields | |

| Published | 2021 |

| Involved Institutes | |

| Project Type | ICNAP Research/Transfer Project |

| Responsibles |

One focus of the current sprint is to determine the potential of unsupervised learning autoencoder models for low-dimensional structures in camera monitoring data for additive manufacturing via Laser Material Deposition. By synchronizing the reconstruction error with TCP coordinates of the LMD process, the spatially resolved investigation of a correlation of anomalies in the images with quality characteristics of the manufactured workpiece is enabled. For example, adhesions occurring on specimen surfaces during the process can be detected more reliably in the measurement data than with the sole observation of the molten pool surfaces.

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

© Fraunhofer 2026